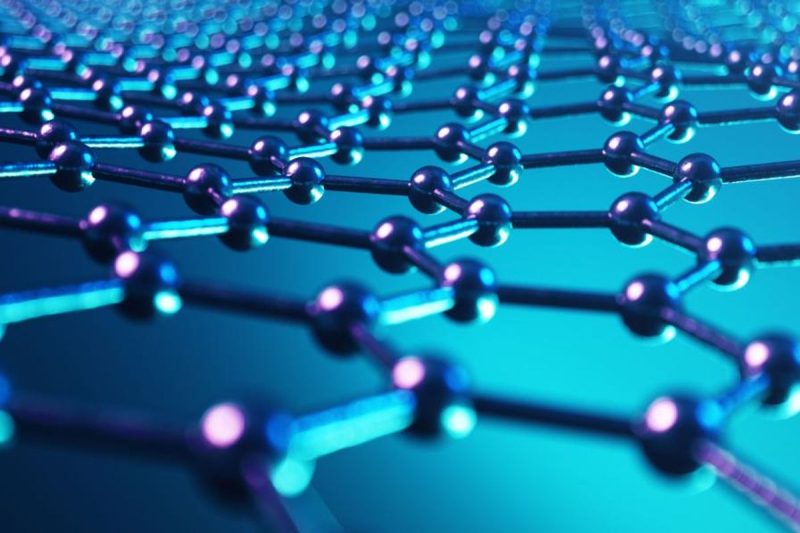

The cost of graphene has been a topic of interest and research within the scientific community for many years. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has exceptional properties such as high electrical and thermal conductivity, mechanical strength, and transparency. These unique characteristics make graphene a highly sought-after material for numerous applications, including electronics, energy storage, and sensors. However, the high production cost of graphene has been a significant barrier to its widespread adoption.

Several factors contribute to the cost of graphene production. These factors include the raw materials used, the production methods employed, and the scale of production. Understanding these factors can help researchers and manufacturers find ways to reduce the cost of graphene and make it more accessible to various industries.

One significant factor affecting graphene cost is the raw material used. Graphene can be produced from different sources, including natural graphite, chemical vapor deposition (CVD) synthesis, and exfoliation of graphite oxide. Natural graphite is the most common source, but it requires intensive purification processes, which can be expensive and time-consuming. On the other hand, CVD synthesis allows for large-scale production of high-quality graphene, but it requires specialized equipment and controlled environments, which adds to the overall cost. Researchers are continually exploring alternative raw materials and methods to make graphene production more economical.

The production method employed also plays a crucial role in the cost of graphene. As mentioned earlier, CVD synthesis is a popular method for large-scale production. However, it involves complex and costly infrastructure. Other methods, such as chemical exfoliation, are relatively cheaper, but they usually yield lower-quality graphene. Improving the efficiency and yield of these production methods would help reduce the cost of graphene significantly.

The scale of production is another factor that impacts the cost of graphene. Currently, most graphene production processes are carried out on a small scale due to the technical limitations and high costs involved. Scaling up the production process would allow for economies of scale, leading to lower costs per unit. Investments in research and development, as well as collaborations between academia and industry, can accelerate the scaling-up process and help drive down the cost of graphene.

Government policies and regulations can also influence the cost of graphene. Supportive policies and funding initiatives aimed at promoting graphene research and development can have a positive impact on reducing production costs. Additionally, regulations related to the environmental and health aspects of graphene production might impose additional costs on manufacturers.

As more research is conducted and technological advancements are made, the cost of graphene is expected to decrease. Researchers are continually exploring innovative methods for efficient production, such as chemical doping and the use of 3D printing techniques. Furthermore, the development of graphene-based composite materials and hybrids can provide a cost-effective solution for a wide range of applications.

In conclusion, while the cost of graphene has been a significant challenge hindering its widespread adoption, various factors influence its production cost. The choice of raw materials, production methods, scale of production, government policies, and technological advancements all play a crucial role in determining the cost of graphene. Continued research and investment in graphene production techniques are necessary to drive down costs and make this remarkable material more commercially viable for various industries. With further advancements, graphene has the potential to revolutionize numerous fields and unlock its full potential as a game-changing material of the future.